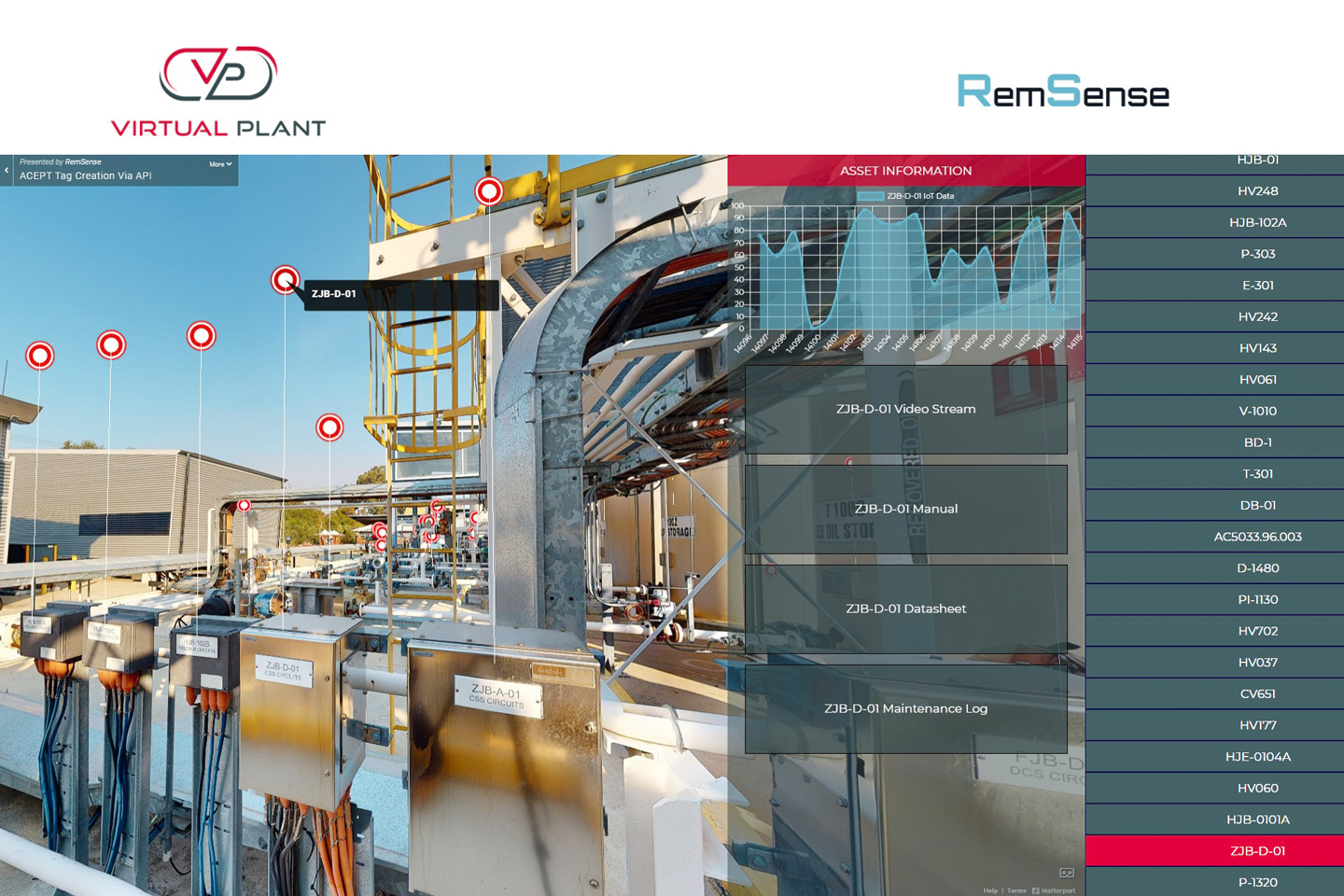

RemSense’s Virtual Plant is a photographic Virtual Reality platform that enables companies to view their assets in extraordinary high resolution. Accessible on laptops, phones and VR headsets, Virtual Plant creates a visual ‘fabric’ that users can move through, viewing assets in detail as they appear on site, without any rendering or use of 3D models.

Virtual Plant has already been deployed across several sites in Western Australia, where it has improved maintenance planning and reduced site visits for employees and contractors. With a surprisingly low set-up cost, fast implementation and no need for any specialised hardware, software or training, Virtual Plant is a quick win for sites looking to improve efficiency without a large cost outlay or long payback period.

Now RemSense has increased the power of Virtual Plant by utilising Artificial Intelligence (AI) to scan the Virtual Plant environment for text. This enables users to generate a list of almost every tag, label, sign, and ID number contained within an entire asset and to locate information on the Virtual Plant fabric.

The key benefit of incorporating AI into Virtual Plant is that it reduces the time taken to link equipment items within the photographic fabric to clients’ existing asset management, maintenance management, safety, and other software systems.

This enables: -

- Virtual Plant to act as a visual hub to display information from existing client databases

Users will be able to have direct links to existing asset and maintenance records, historical inspection photos, training videos and operating manuals using the client’s equipment ID tag as a common key.

- Data Validation between physical assets and digital records

Users will be able to identify discrepancies between what exists at a physical asset and what is represented in various systems that together form a company’s overall data lake.

- Direct navigation within Virtual Plant to a particular asset

The photographic fabric of Virtual Plant will not only be searchable – users can simply type the ID / tag number and Virtual Plant will take them directly to the specific piece of equipment.

With many asset managers and owners seeking to leverage digital technologies to gain efficiencies, Virtual Plant offers a cost-effective way to start their digital journey whilst generating significant productivity and safety gains. Similarly, because of its low cost and quick payback period, it can easily be added into a company’s suite of digital tools, with the ability to tailor which data links to apply according to the company’s needs.

“We have seen the adoption of Virtual Plant grow organically within our client’s business, with employees finding their own use cases according to their needs. It fosters collaboration across functional teams and remote locations, and this wouldn’t be possible without a high degree of accessibility, speed and resolution” CEO Steve Brown commented.

RemSense’s utilisation of AI to enhance Virtual Plant builds off their prior experience of using AI to interpret photographic, sensor and geospatial data from drones.

“The value AI has generated for our clients from images and sensor data we’ve captured is compelling. It was a natural progression to apply this expertise to Virtual Plant as well”

“At its core, Virtual Plant is visualisation platform that enables significant operational improvements with numerous use cases. However, the adoption of AI is gamechanger – not only does it allow users to find and organise the huge amount of visual information that exists across an asset, it also creates keys to link Virtual Plant to other platforms within a company’s digital ecosystem.”

Virtual Plant can be configured to suit individual client requirements with the implementation of additional features. This can be undertaken well after the initial site scan has been completed and the environment is live on a client’s site. This flexibility allows a client to use and experience Virtual Plant across their organisation and progressively build on their initial investment.

Available enhanced features: -

- Links to existing client databases (asset, engineering, maintenance, safety)

- Display current and historical data from IoT enabled equipment and sensors

- Display live webcams including thermal imaging

- Link operating and/or maintenance manuals and videos

Developed by RemSense in close cooperation with Woodside Energy under RemSense’s Technology Development as a Service (TDaaS) engineering model, Virtual Plant is just one of many projects being undertaken providing productivity and cost saving solutions across a wide range of engineering disciplines to Australian industry.

For more information about Virtual Plant or the TDaaS service, please contact the RemSense team at info@remsense.com.au or 08 6118 5610