ASX-listed Altech Chemicals’ 75 per cent-owned German subsidiary, Altech Industries Germany is set to begin a pre-feasibility study, or “PFS” on the potential construction of a battery materials high purity alumina, or “HPA” coating plant in Germany.

The Perth-based company says the PFS will assess the commercial viability of building the plant, which would coat anode-grade battery materials with HPA using its own alumina coating technology.

The plant would be built at the Schwarze Pumpe Industrial Park in Saxony, where Altech’s German subsidiary has an option to buy an approximate 14-hectare site. In the event the development goes ahead, Altech says the plant’s output is intended to contribute to the supply requirements of the rapidly growing European lithium-ion battery industry.

Altech, who envisages the coating plant’s HPA feedstock requirement would eventually be satisfied from its proposed Malaysian HPA plant, expects the PFS to kick off next month.

Germany last year unveiled a €130 billion Coronavirus economic stimulus package that, Altech points out, includes support for the electric vehicle industry, one of the chief sources of predicted growing demand for lithium-ion batteries.

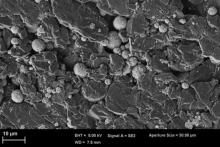

Altech says it recently carried out successful trials demonstrating its alumina coating technology to coat graphite particles, typical of those used in anode applications within lithium-ion batteries, with a nano layer of HPA.

According to the company, the demonstrations undertaken at universities in WA late last year showed its technology was able to deposit a uniform and consistent layer of alumina approximately 2 nanometres thick onto anode-grade graphite particles.

Uniformity and consistency of an alumina layer or coating on anode-grade graphite are expected to be important, the company says, in the improvement of lithium-ion battery performance and life.

Following the completion of the demonstration, the company produced a sufficient quantity of coated graphite to proceed to a first stage of battery performance testing of batteries containing the alumina coated graphite particles. The test work is under way.

HPA is commonly applied as a coating on the separator sheets used in lithium-ion batteries, with the alumina-coated separators improving battery performance, durability and safety.

Is your ASX-listed company doing something interesting? Contact: matt.birney@businessnews.com.au